Description

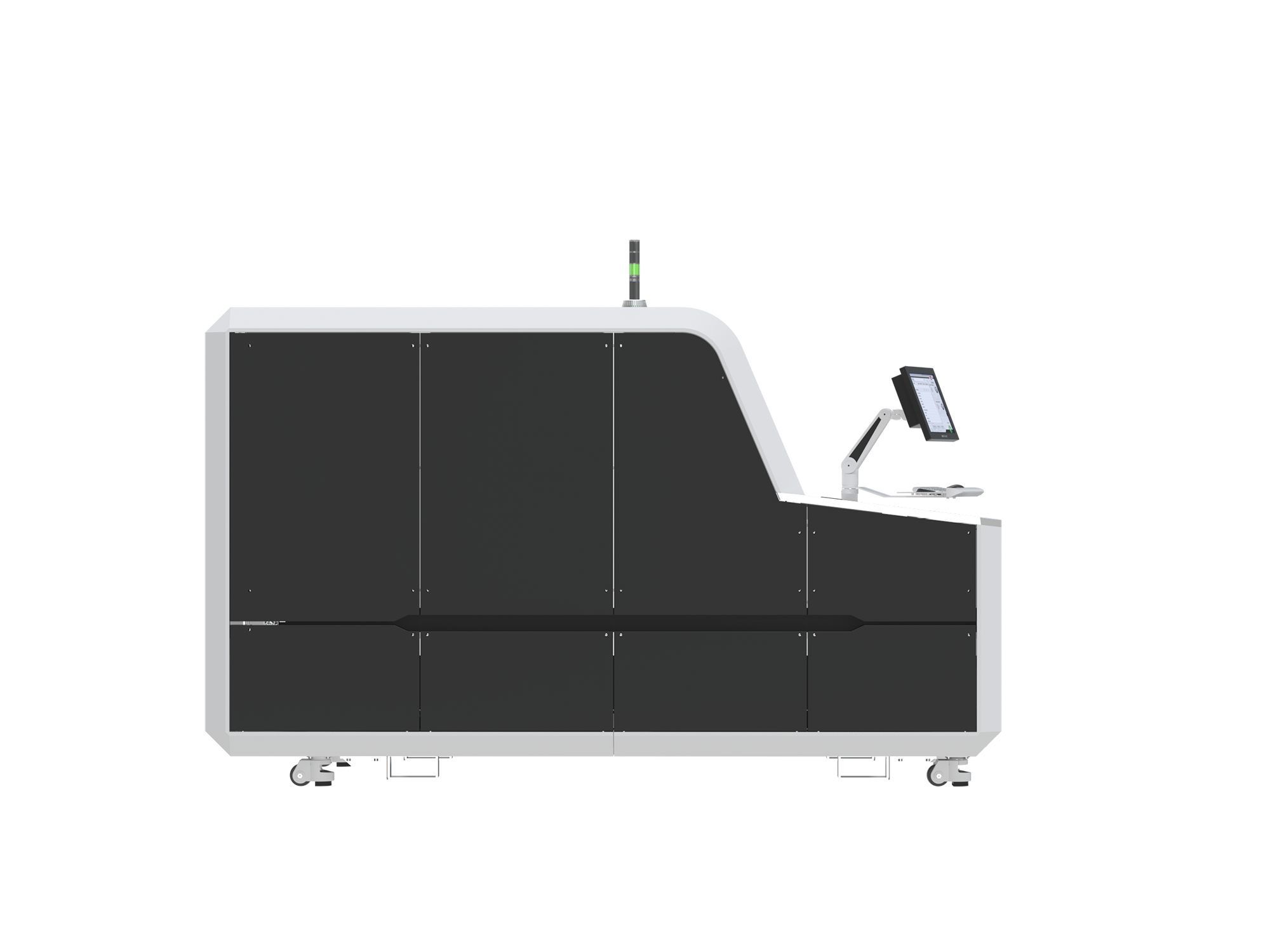

The LIMATA X2000 Series is LIMATA’s direct imaging system platform designed for the imaging of Dry-Film and Solder Mask applications in high-volume PCB production environments.

LIMATA’s combined UV/IR imaging approach for solder mask applications accelerates the UV polymerization process and ensures significant higher throughput levels (surfaces per hour) on high-energy solder resist inks.

Fully-integrated single and dual-system automation options for an Island of Automation or in-line DI operation Setup can be provided.

Key system features

- Direct imaging platform for the maskless direct imaging of green, black, blue, white and red colored solder resists

- Integrated dual table system as standard hardware feature for higher production efficiency and throughput levels (panels/h)

- Multi-wavelength LED set-up with >25.000 hours lifetime (MTBF)

- Use of Multi-Wavelength UV-Light to optimize solder resist exposure

- LIMATA’s proprietary UV/IR solder mask imaging technology accelerates imaging speed on all standard solder mask materials (i.e. Tayio)

- RGB & IR camera lightning for easy fiducial detection on all solder mask colors

- Highest optical depth of focus for an uniform power distribution on copper and base material

- Unique modular imaging head concept provides for in-field system capacity upgrades (additional imaging units or IR modules)

- Direct imaging capability on all standard solder resist types (i.e. Tayio)

- Ease-of-use operator friendly data interface

- Designed to minimize maintenance, downtimes and service costs over the entire DI equipment lifetime

Imaging technologies

- High-speed Galvo-Scan Laser Technology or Real UV DMD/DLP chipse

- UV- diode laser or multi-wavelength UV-LED setup

- IR-Module (for solder mask applications) / LUVIR Technology

- Highly telecentrical optical system incl. auto-focus functionality

Modular direct imaging set-up

- Based on the specific solder mask ink type and color, energy levels (mJ/cm2) and direct imaging capacity requirements, the optimum UV-laser/LED and IR-imaging Setup can be selected and configured according to individual customer capacity needs

- Possibility to conduct in-field upgrades for increased imaging capacities (additional imaging heads and IR modules) enabled by a modular „plug-in” concept.

Imaging and Software options

Advanced IC substrate capability down to

12 um / 0.6 mil Line / space with industrial

speed

Detection of multiple fiducials for maximum registration accuracy

Automated tracking of individual Barcodes or serial numbers for full product traceability

MES-interface and Secs/Gem programming options (“real-time“ production data)

DI Automation (Island of Automation / In-line)

PCB Applications (solder mask imaging)

Standard PCB and HDI

- Standard (rigid)

- Standard (flex)

- Standard (rigid-flex)

- Any layer PCB

- mSAP (semi-additive)

Solder resist colors

- Green

- Black

- Blue

- White

- Red