DI Process Automation

In addition to its DI systems product line, LIMATA offers its customers complementary automation and PCB handling options for a fully integrated “Island of Automation” or “In-Line” DI process operation.

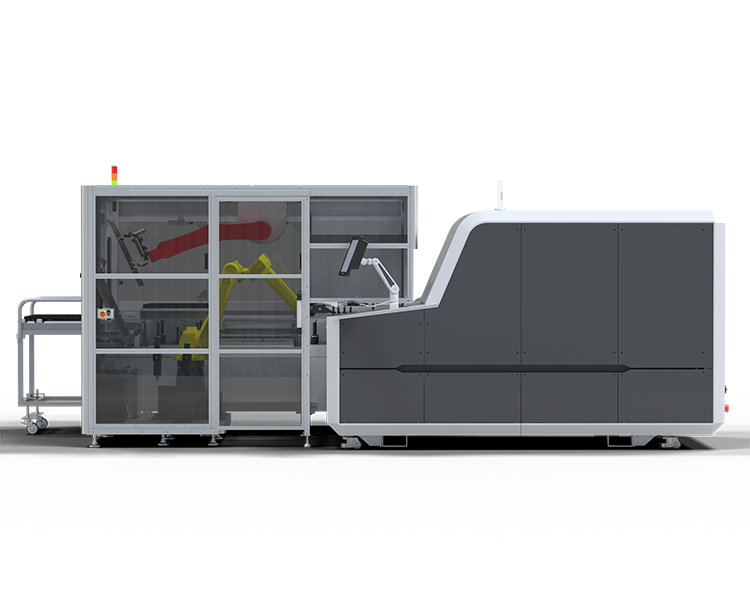

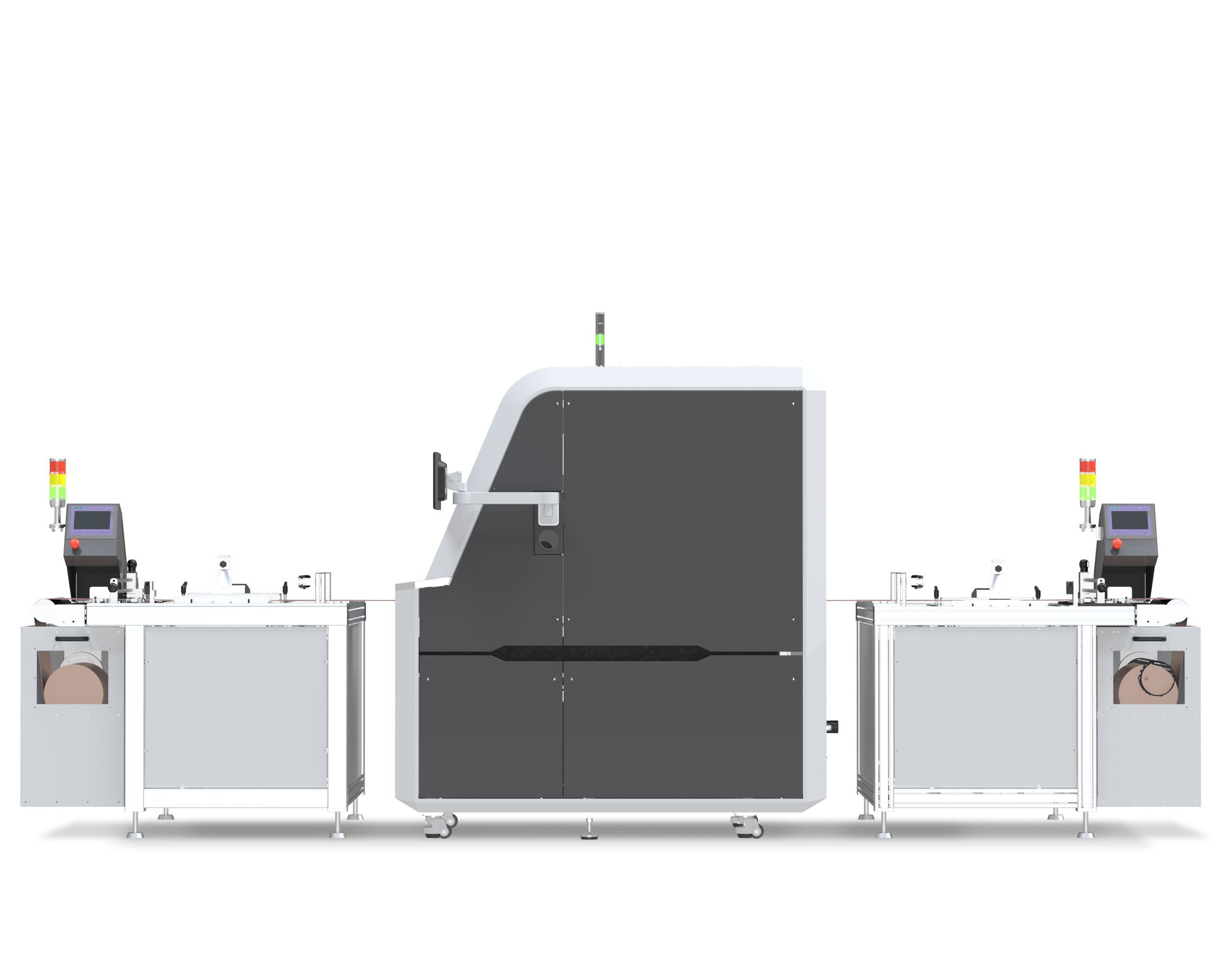

X1000A Single & Twin automation fully modular in-line

The new LIMATA X1000A series combines LIMATA’s flexible direct imaging system platform (X1000) with a new in-house developed, fully automated panel handling set-up (loader, inverter and unloader) to a fully Automated Digital Imaging (ADI) in-line solution for e.g. the PCB solder mask and/or outer layer process.

- Flexible Digital Imaging system solution with modular system and imaging capacity options based on LIMATA’s X1000 system platform (1-3 heads per system)

- Fully automated panel handling and digital imaging (as one combined process step) without the need for permanent manual operator support

- Available as “single” and “twin-set” DI configuration with field-upgrade capability

- Fastest exposing of conventional solder mask inks powered by LUVIR Technology® (UV+IR)

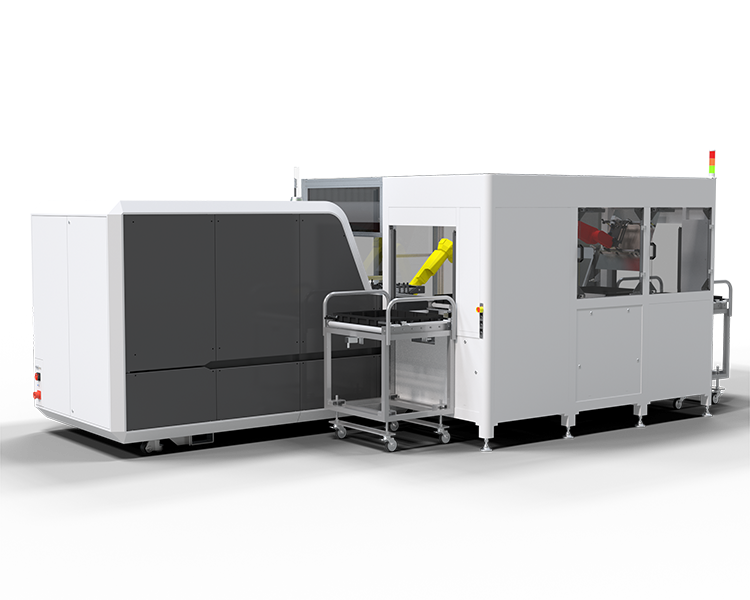

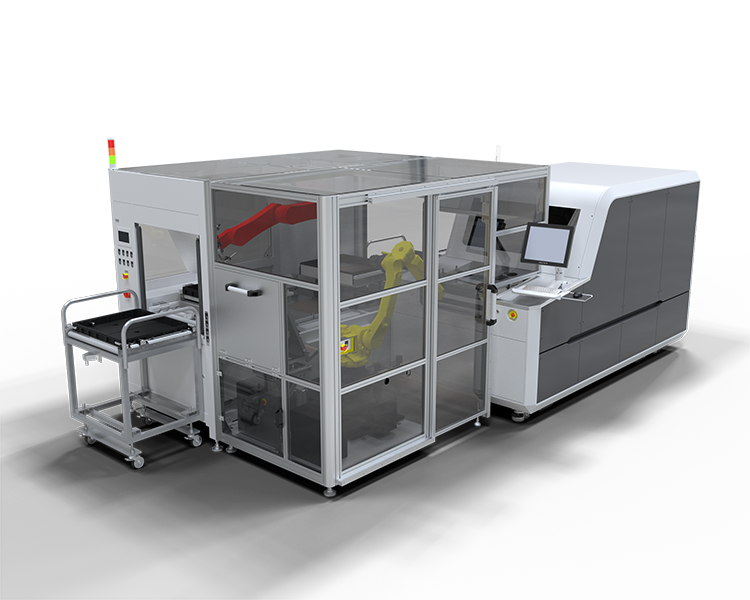

X2000 Island of Automation (LIMATA Single DI)

The X2000 platform can be complemented by a robot automation (LIMATA or 3rd party vendor) for an automated handling of inner and outer layer PCB at lower process costs and no cycle time reduction based on loading/unloading times.

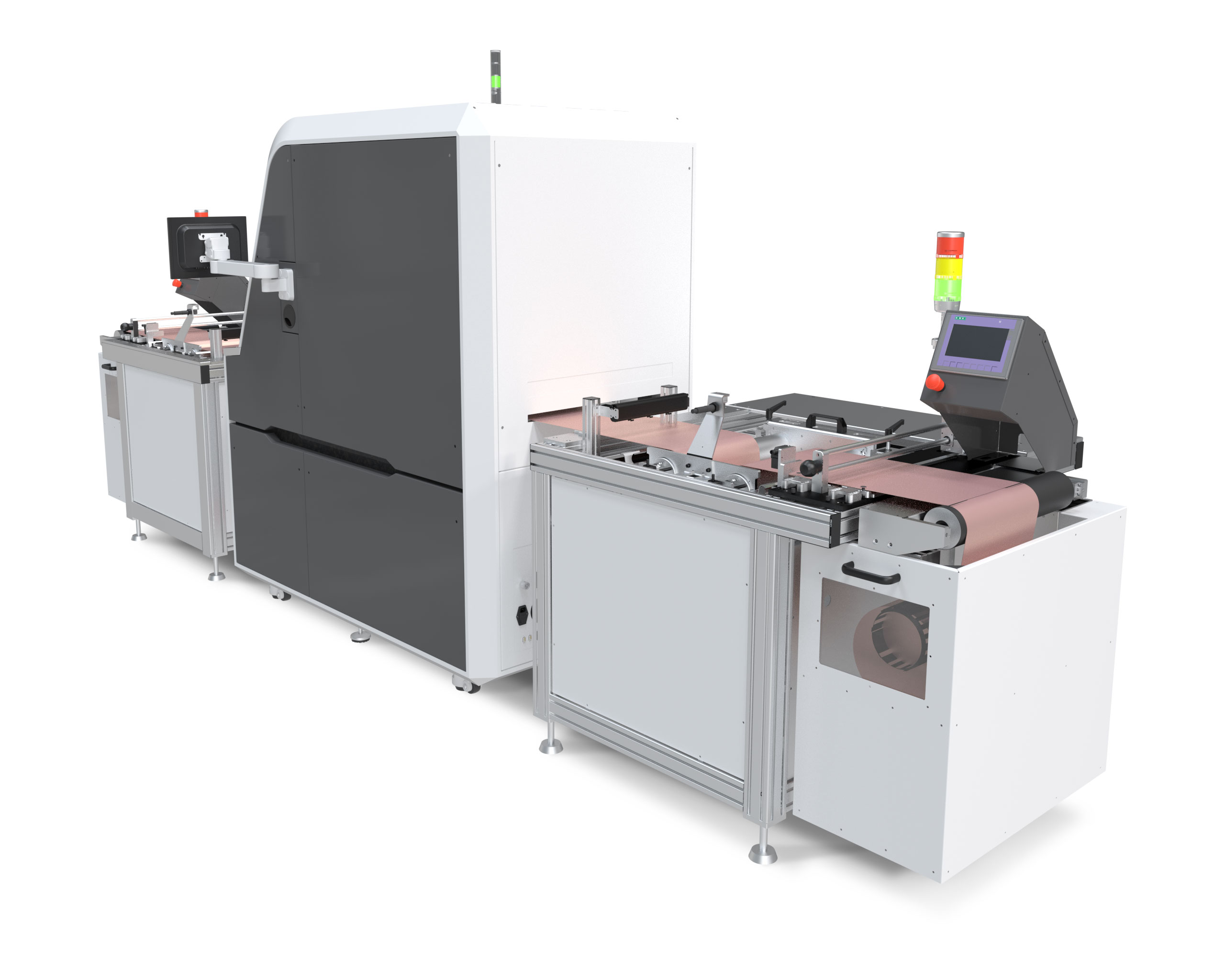

Reel-to-Reel Automation (X1000 R2R)

The X1000 platform is available with a Reel-2-Reel automation set-up (winder/unwinder) for a fully automated and efficient production of Flex PCB’s. The labor-free automation of the loading / unloading process increases capacity and reduces overall process costs and costs per panel.