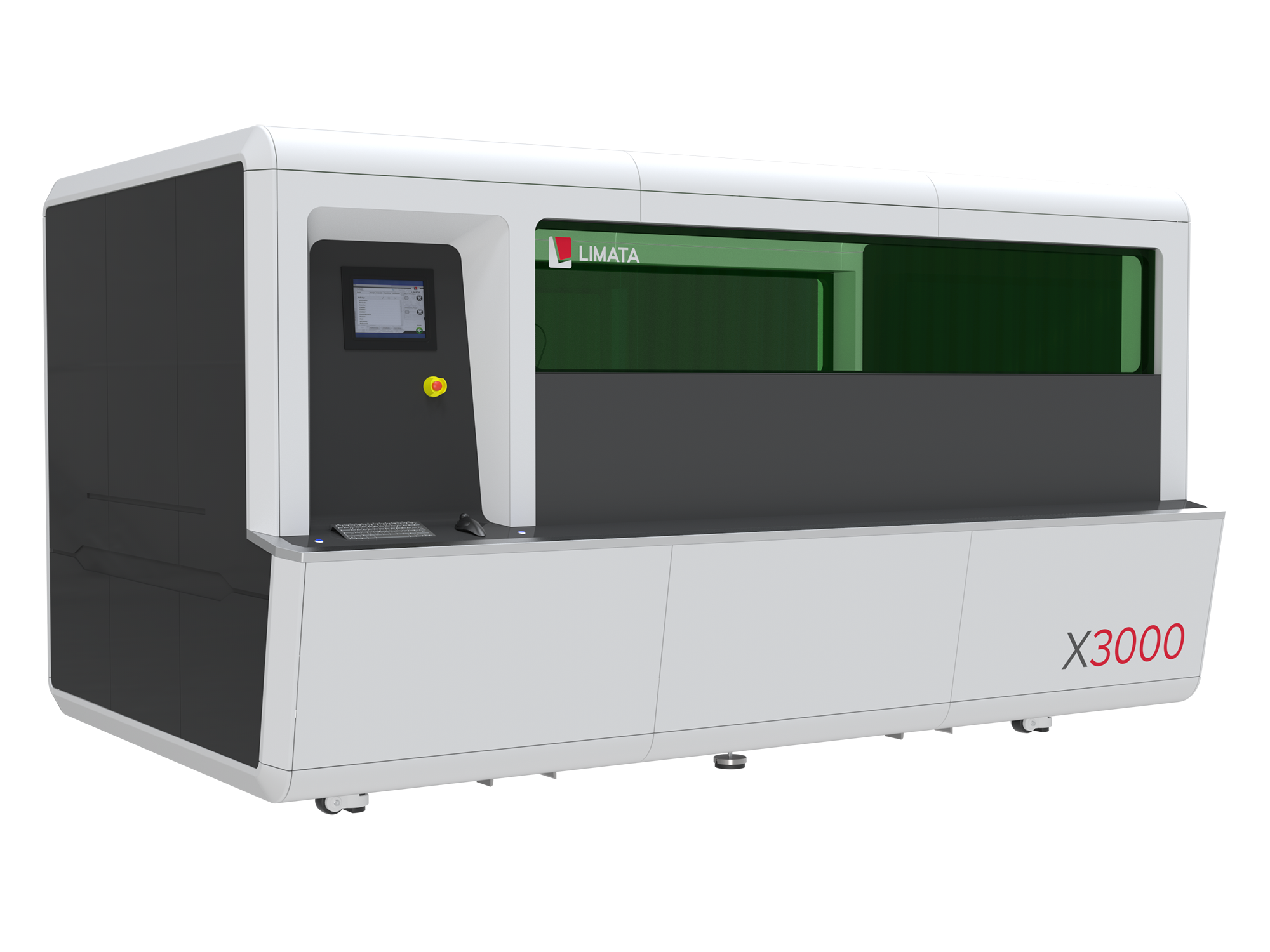

X3000

Description

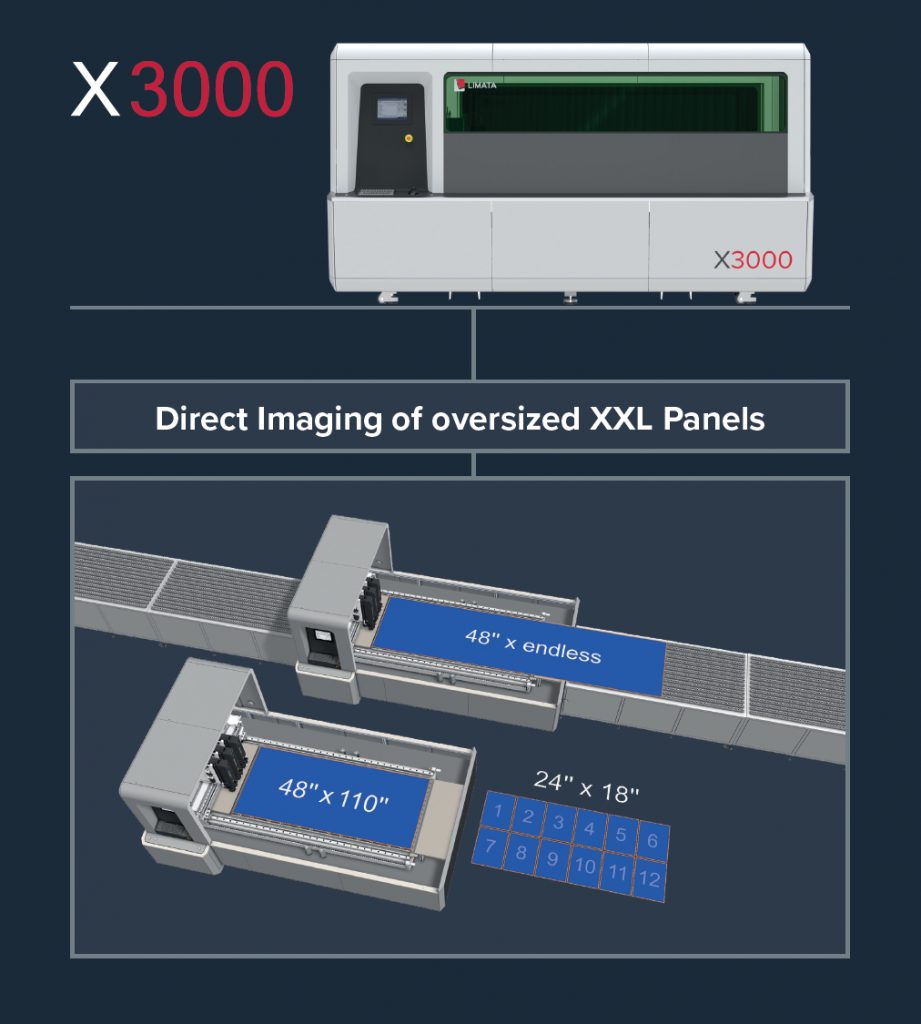

The LIMATA X3000 Series is an unique direct imaging system platform designed for the imaging (patterning) of oversized PCB boards. The X3000 series can image panel sizes of up to 110” x 48” with highest DI precision in registration and resolution. A hybrid system Setup can be configured for PCB customers who want to process both, dry-film patterning and solder mask imaging, on one DI system platform.

Key system features

- Working/Imaging area of up 110” x 48 provides for extreme large panel manufacturing

- Multi-wavelength LED set-up with >25.000 hours lifetime (MTBF)

- Highest optical depth of focus incl. auto-focus functionality

- Unique modular imaging head concept provides for redundancy and in-field system capacity upgrades (additional imaging units)

- Direct imaging capability on all standard resist types (Hitachi, Asahi, etc.)

- Ease-of-use operator friendly data interface

- Designed to minimize maintenance, downtimes and service costs over the entire DI equipment lifetime

Optional Solder mask imaging capability

- LIMATA’s proprietary UV/IR solder mask imaging technology accelerates imaging speed on all standard solder mask materials (i.e. Tayio)

- RGB & IR camera lightning for easy fiducial detection on all solder mask colors

Imaging technologies

- High-speed Galvo-Scan Laser Technology or Real UV DMD/DLP chipset

- UV- diode laser or multi-wavelength UV-LED setup

- Highly telecentrical optical system incl. auto-focus functionality

- Optional: IR module for solder mask imaging of XXL boards

Modular direct imaging set-up

- Based on each customer‘s individual oversized PCB specification, L/S resolution and direct imaging capacity requirements (prints/hour), the optimum imaging Setup (ranging from 1 to 4 exposure heads) can be selected and configured according to customer needs

- Optional: IR module for solder mask imaging capabilities

- Possibilty to conduct in-field upgrades for increased imaging capacities (additional imaging heads) enabled by a modular „plug-in“ concept

X3000 - Options

Advanced IC substrate capability down to 12 um / 0.6 mil Line / space with industrial speed

Detection of multiple fiducials for maximum registration accuracy

Automated tracking of individual Barcodes or serial numbers for full product traceability

MES-interface and Secs/Gem programming options

(“real-time“ production data)

The X3000 platform can be complemented by a robotic set-up for a fully automated and less labor intensive LDI in-line operation

PCB Applications

Oversized PCB boards

- XXL boards (up to 110“ x 48“)

- Endless boards (roll-to-roll)

- Flex panels for wiring

Markets

- Military & aerospace

- Industrial

- Clean energy