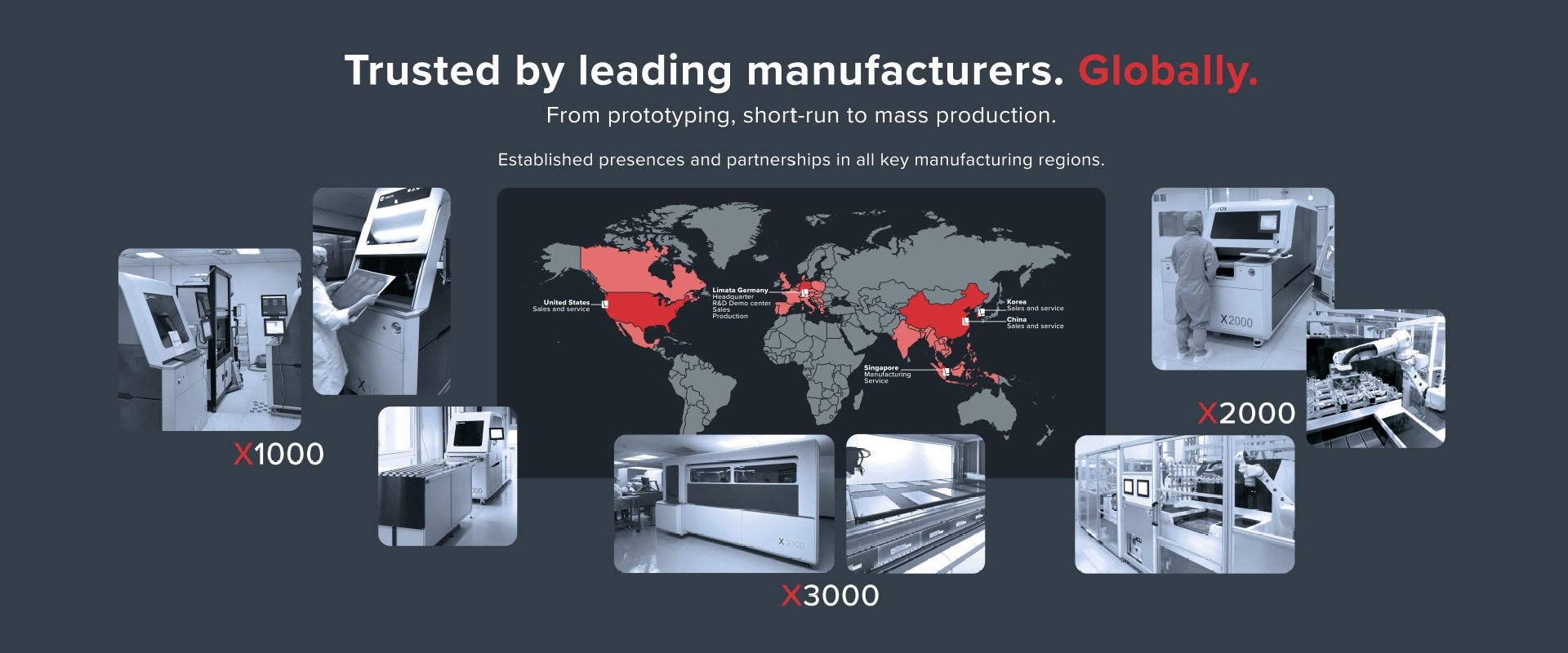

We are an innovative supplier of maskless direct imaging (DI) system solutions for various PCB manufacturing environments and adjacent markets. Our system product portfolio ranges from DI system configurations for high-mix and emerging PCB niche applications up to fully automated DI system solutions for mass production environments.

We are an entrepreneurial, innovation and customer driven organization with staff, operations and/or value adding sales partnerships in all key PCB manufacturing regions. The core of our operation is Ismaning near Munich (Germany) which is also home to our R&D/development, engineering and applications team.

Increased technical requirements in PCB manufacturing driven by more advanced PCB designs (towards thinner materials, more complex and finer structures at only small design rule tolerances) have set limitations for the conventional mask contact lithography (phototool) method in particular for the production of more advanced PCB applications.

Key advantages of the Direct Imaging (DI) technology include:

- Higher accuracy in registration as well as printing (line uniformity)

- Higher depth-of-focus

- Full product and process traceability during the manufacturing process (data interfaces)

- Higher productivity and quality levels (throughput and yields) during PCB production

- Lower process costs and total costs of ownership versus conventional mask/film lithography during the pattern or solder mask process

Backed by a dedicated in-house hardware & software engineering team, LIMATA has developed a complete DI system product line – X-Series for the PCB patterning and solder mask process.

Key imaging components used in LIMATA‘s system solutions consisting of DMD/DLP units, UV-LED & Laser diodes and optics have been either developed internally or in-close cooperation with key component suppliers. A fully in-house developed software platform completes LIMATA‘s system product offerings.

It was a pleasure to welcome so many visitors from all over the globe at the 𝗟𝗶𝗺𝗮𝘁𝗮 𝗯𝗼𝗼𝘁𝗵 𝗶𝗻 𝗛𝗮𝗹𝗹 𝗕3, 𝗕𝗼𝗼𝘁𝗵 233.